Emission is the release of gaseous, liquid or solid substances from industrial facilities or materials into the environment. Also vibrations, noise or radiation can be emitted. The main factor influencing indoor air quality is the emission of gaseous organic compounds (VOCs: see question 2) – above all the type and quantity.

VOCs are volatile, organic compounds that change from the liquid to the gaseous state at room temperature and normal pressure. Typical VOCs include all organic solvents, but also fuels such as gasoline, diesel oil and the like. Unfortunately, there is no generally binding definition of VOCs. Some of the definitions differ significantly from each other.

The European Directive 2010/75/EU (IED Directive) defines VOCs as organic substances whose vapor pressure is 0.01 kPa or more (at room temperature T = 20 °C = 293.15 K). This definition is almost identical with the definition of solvents under question 3. A different definition is given by European Directive 2004/42/EC (Decopaint Directive).

According to this Directive, all volatile substances with a boiling point or initial boiling point of 250 °C or lower (at normal pressure p = 101.3 kPa) are to be regarded as VOCs.

VOCs with a boiling point above 250 °C are referred to as SVOCs (Semi-Volatile Organic Compounds). TVOC (Total Volatile Organic Compounds) is the sum of all VOC values measured for individual substances, while TSVOC is the sum of all individually measured SVOCs.

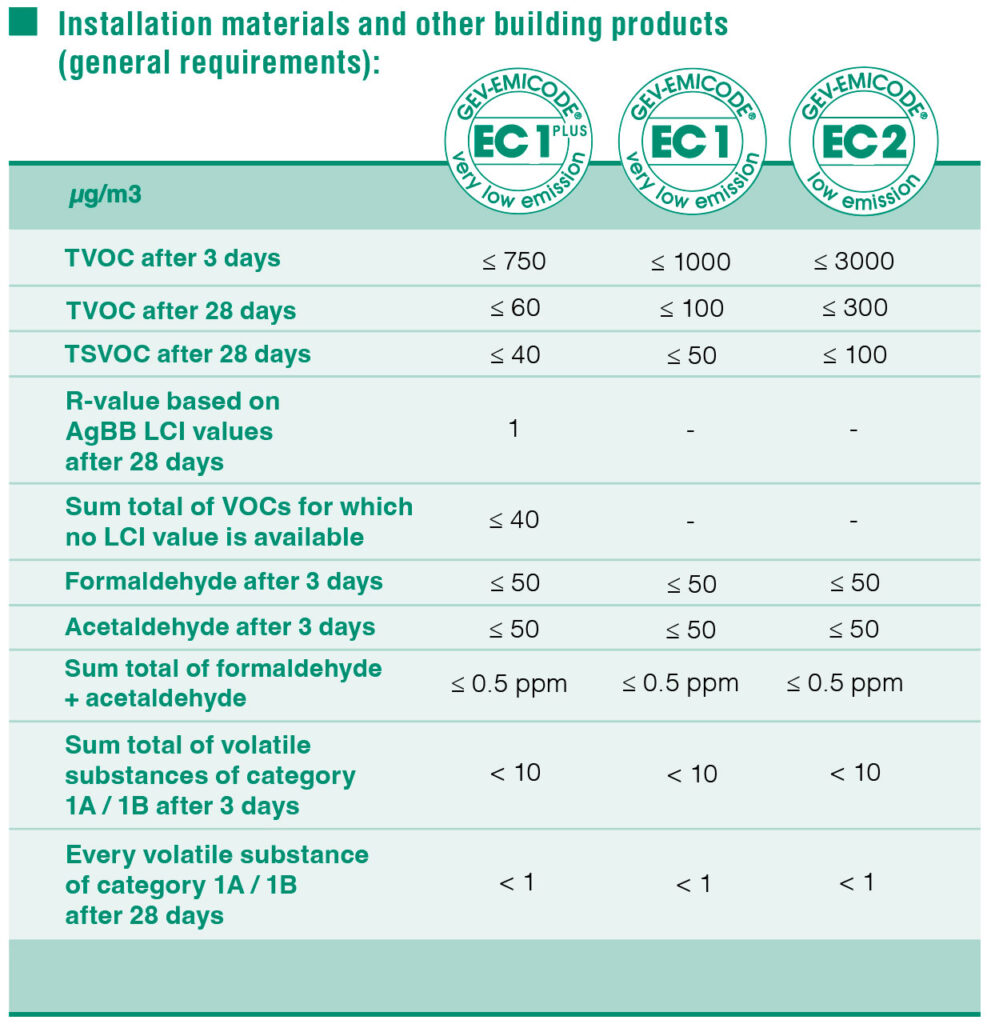

In addition to the total sum of emissions, a so-called “Lowest Concentration of Interest” (LCI value) has been defined for the individual evaluation of many substances. To obtain EMICODE® class EC 1PLUS, an individual substance evaluation is carried out on the basis of LCI values.

Generally speaking, solvents are liquid substances in which other substances dissolve. These can either be of an inorganic (e.g. water) or organic nature. In our context, however, we usually mean organic solvents – as defined, for example, in TRGS 610, the “Technical Rules for Hazardous Substances” (important for Germany). These rules define solvents as organic substances with a boiling point of 200 °C or lower. Concerning surface treatment agents for parquet, the term “solventì is defined by TRGS 617 as a substance with a boiling point of 250 °C or lower. Solvents are used to dissolve other substances and are expected to evaporate more or less quickly after application of the product, e.g. a paint or adhesive. Plasticizers are relatively non-volatile and are therefore classified as SVOCs rather than VOCs.

VOCs can have different sources. For example, building products may contain solvents that evaporate intentionally or unintentionally. But also other materials, furnishings or devices may contain organic substances that release VOCs into indoor air. Examples include chipboards, building materials, textiles and plastics, wood, wool, perfumes, scented candles, air fresheners, photocopiers, care products, nail polish removers, cosmetics and many more. These VOCs can be the result of production processes (e.g. residual solvents from a furniture varnish), degradation reactions of organic substances caused by the presence of atmospheric

oxygen, by light or by rot and mold (microbial VOCs, so-called MVOCs). Also humans, animals and plants emit significant amounts of VOCs. Indoor air can therefore be polluted by VOC emissions from a variety of sources. In newly finished rooms, it is particularly freshly applied paints, adhesives, sealants but also new furniture and home textiles that temporarily increase the TVOC concentration.

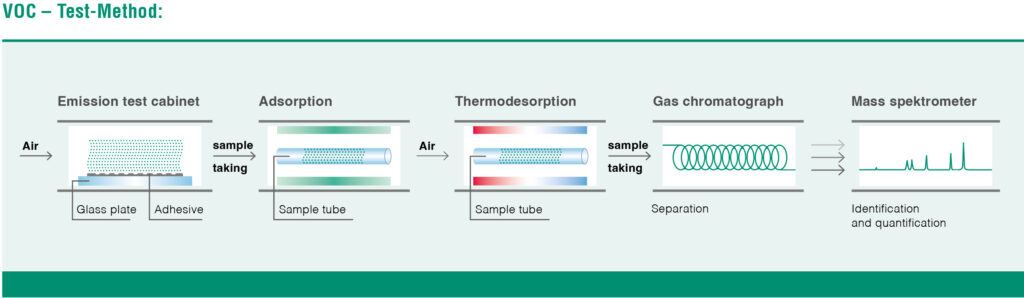

With the help of modern, highly sensitive laboratory testing, e.g. by means of gas chromatography (GC) and mass spectrometry (MS), even the smallest traces of VOCs in the air can now be detected and quantified. The emission behavior of materials can be determined in special test chambers from which air samples are taken and analyzed after predefined measuring times. VOC concentrations are indicated in mg/m3 or µg/m3, i.e. thousandths or millionths of a gram per cubic

meter of air. The sum total of individual VOC concentrations is the TVOC value (total concentration of VOCs).

Substances that are known to be harmful to health, toxic, carcinogenic or otherwise hazardous are subject to limit values, restrictions on use and labeling requirements. However, there is little scientifically proven knowledge about the effects of many other VOCs, especially when only low concentrations are involved. Since many VOCs are suspected of having a negative impact on our well-being and health, either alone or in combination, scientists around the world are now working on ways to prevent VOC emissions. Some EU countries, especially Belgium, Germany and France, have national regulations for the VOC and SVOC contents of certain products.

In the so-called Seifert study, conducted in 1985/86, the Federal Health Agency of that time requested the measurement of VOC concentrations in indoor air of approx. 500 German households. More than 50 different substances were found. Total concentrations varied widely from household to household, ranging from 170 to 2600 µg/m≥. The statistical analysis of this study showed a mean value (50th percentile or median) of approx. 330 µg/m≥, which was rounded to 300 µg/m≥. Since then, it has been regarded by many experts as the target value to be achieved.

In 1990, Seifert himself stated at the Indoor Air Conference in Ottawa that the 300 µg/m≥ TVOC value and the values for individual VOC groups were only target values to be achieved in the long term ñ without toxicological evaluation. For newly renovated rooms, for example, he described an exceedance of these values by a factor of 50 after 1 week and by a factor of 10 after 6 weeks as perfectly acceptable.

Due to much more refined test methods and systems today, it can be assumed that a considerably larger number of substances would be found today, resulting also in higher normal values. Moreover, also the product composition has changed significantly. It is important to understand that Seifert’s target value of 300 µg/m≥ for indoor air, which is affected by numerous complex factors, has nothing whatsoever to do with the test chamber values obtained for individual products or materials. Test chamber values allow a relative evaluation of products (ranking), but do not provide information about expected indoor air concentrations.

Often, natural or organic products even have higher VOC emissions than synthetic products. In natural adhesives, for instance, natural tree resins, turpentine oils and other substances are used, which emit considerable amounts of so-called terpenes. These can cause typical odors and high TVOC levels in indoor air.

Renowned manufacturers of flooring adhesives decided to develop low-emission flooring installation products and promote their use in the market. In order to create a binding basis, the GEV or “Gemeinschaft Emissionskontrollierte Verlegewerkstoffe e.V.” (Association for the Control of Emissions in Products for Flooring Installation) was founded in February 1997.

To meet the market’s demands for testing further product categories, the GEV was renamed in 2007 to “Gemeinschaft Emissionskontrollierte Verlegewerkstoffe, Klebstoffe und Bauprodukte e.V.” (Association for the Control of Emissions in Products for Flooring Installation, Adhesives and Building Materials). Every manufacturer of such products can become a GEV member. Sponsoring memberships are possible and very welcome.

The GEVës main task is the promotion of safety at work as well as consumer and environmental protection concerning the use of chemical building products. The association pursues an open information policy and supports cross-vendor cooperation with all partners in the industry.

The first and foremost goal was to give the market a tool that allows users a vendor-neutral assessment of the available products and enable them to compare the numerous flooring installation materials, adhesives and building products with respect to their VOC emissions. For this purpose, the EMICODEÆ classification system was developed.

In January 2025, the GEV had 250 ordinary members and 2 supporting members from 24 countries. You can find the current list of members on www.emicode.com/en/en-members. Of course, you can also request the list by phone or email.

info@emicode.com

Phone: +49 (0)211 / 843 449–01

Worldwide, any manufacturer of flooring installation materials, adhesives, building products or raw materials can become a member if the company agrees to comply with the GEV’s Constitution and to promote the GEV’s objectives.

EMICODE® is the trademark-protected name of a classification system that is used to classify flooring installation materials, adhesives and building products according to their emission behavior into one of the following three classes:

EMICODE® EC 1PLUS

EMICODE® EC 1

EMICODE® EC 2

Classification according to the EMICODE® system is based on analytically determined measurement data and on concrete classification criteria, obtained using a defined test method. Since the term “low-emission” has neither been standardized nor clearly defined, the EMICODE® system provides a binding basis for the assessment and selection of flooring installation materials, adhesives and building products.

Early 1997 the EMICODE® classification system was initially developed for flooring installation products (primers, fillers and flooring adhesives) with the focus on indoor air hygiene. By now, the spectrum has been expanded considerably.

Meanwhile, the EMICODE® classification criteria have been adapted at the request of other industrial sectors. The special advantage of the system is that the methods of testing, certification and control are always tailored to the specific characteristics of the building materials and product categories. For an overview of the current categories and products please refer to www.emicode.com/en/produkte.

Class EMICODE® EC 1PLUS is currently the highest standard for low-emission products and thus represents the limit of what is technically feasible today. This class is the systematic further development of class EMICODE® EC 1, established and well-proven until 2010 – only at a much higher level and with much stricter limit values.

Within the EMICODE® system, the classification ranges for TVOCs (total volatile organic compounds) and TSVOCs (total semi-volatile organic compounds) as well as for individual substances have been defined as follows:

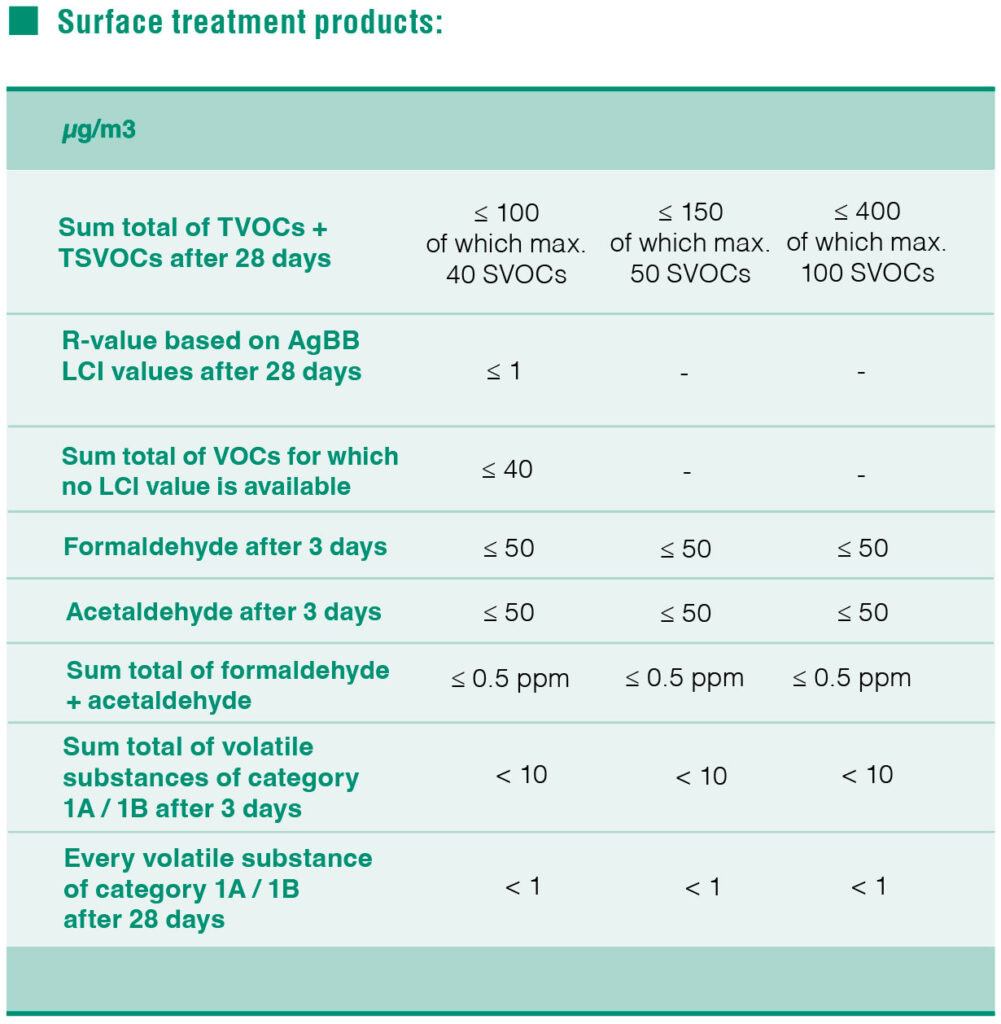

The EMICODE® classification system distinguishes between two large product groups: the very broad group of flooring installation materials, adhesives and building products and the smaller group of surface treatment products for service floors. The EMICODE® system always reflects the state of the art as well as any identifiable options and needs for further development.

The requirements for the various products, laid down in the classification criteria, are so demanding that technical progress is promoted and product optimization becomes necessary. As the state of the art differs for the two product groups, it is reflected in slightly different requirements.

A product intended for EMICODE® labeling must fulfil a number of important basic requirements. Adhesives, for instance, must be free of solvents and have a boiling point below 200 °C. A trace amount of max. 0.5 % is tolerated as it is often unavoidable for technical reasons. Furthermore, the emission of certain C‑substances (see question 19) must be below specified limits after only 72 hours in the test chamber. In addition, an EU Safety Data Sheet must be available for the product.

Classification into one of the three EMICODE® classes depends on the total emission of TVOCs and TSVOCs. These values are determined in the test chamber using the applicable GEV test method. Test methods and classification criteria are laid down by the GEV’s Technical Council. This is elected every two years by the GEV’s General Assembly and supported by external experts. The Technical Council is also responsible for continuously updating the methods and classification criteria and for further developing the EMICODE® system.

Generally speaking, C‑substances are carcinogenic substances. They are subdivided into three categories.

Category 1A: Substances known to have carcinogenic potential for humans.

Category 1B: Substances that are carcinogenic in animal studies and presumed to have carcinogenic potential for humans.

Category 2: Substances suspected of having carcinogenic potential for humans.

When measuring the emissions of a product in the test chamber, air samples are taken after 3 and 28 days to determine whether and in what concentration relevant C‑substances are emitted. To obtain EMICODE® classification, the emissions must not exceed predefined limit values (see question 16).

Testing is carried out with the help of a test chamber procedure that has been developed and defined in cooperation with renowned testing institutes. Depending on the type of product, a characteristic product sample is prepared. An adhesive, for instance, is applied to a predefined test surface. The sample is then placed into the test chamber whose ventilation and climatic conditions have been laid down in EN 16516. The chamber must have a minimum volume of 100 liters. The size of the sample area is calculated to produce emissions of 0.007 to 0.4 m≤/m≥.

The GEV does not carry out tests itself but works with external, independent testing laboratories for this purpose. Several round robin tests have shown that, from a quality, competition and cost point of view, the choice of testing institutes should not be restricted in advance. However, two conditions must be fulfilled:

The laboratories must (1) be proficient in the GEV test method (chamber test) and have the required equipment, (2) be accredited according to ISO 17025. The accreditation must also include the GEV test method or testing according to EN 16516.

The company that commissioned the test is responsible for the respective test result. A list of laboratories that achieved reliable results in the round robin tests initiated by the GEV can be found on www.emicode.com/en/laboratories.

The products that can be tested according to GEV rules and certified with the EMICODE® label are very different. There are, for instance, low-viscosity primers and varnishes that are applied in a thin layer, pasty adhesives or sealants, but also mortars and screeds applied in a thicker layer, as well as sealing tapes or strips, insulation and other materials that are available as finished products in a specific form. Curing takes place by simple drying or by chemical reaction; curing time depends on the layer thickness. For this reason, the sample must be produced specifically for this product group in such a way that the emission behavior in the test chamber is representative of the product.

The correct classification of the product into one of the EMICODE® classes is done on the memberís own responsibility. It is based on the results of the TVOC, TSVOC and C‑substance measurements performed by a suitable testing laboratory. Through their membership, members commit themselves to comply with the GEV’s Constitution and classification criteria. The use of the EMICODE® classification system thus ensures binding and comparable product labeling.

The manufacturer first ensures that the basic requirements for classification into one of the EMICODE® classes have been fulfilled. After that, he submits a formal application for licensing to the GEV. The application must include the test report of the external testing institute, the trade name of the product and an identification number that can be traced back to the product formulation. The issued license is valid for five years.

In principle, only those products can be labeled with the EMICODE® whose manufacturers are GEV members and thus recognize as binding the rights and duties under the GEV Constitution. Each product to be labeled must be assignable to one of the product groups listed in the GEV product matrix and must meet the GEV’s basic requirements (see question 18).

After testing the product with the GEV test method, classification of the product according to the applicable GEV classification criteria and presentation of a valid GEV license, the product can be labeled with the EMICODE®.

In principle, only those products can be labeled with the EMICODE® whose manufacturers are GEV members and thus recognize as binding the rights and duties under the GEV Constitution. Each product to be labeled must be assignable to one of the product groups listed in the GEV product matrix and must meet the GEV’s basic requirements (see question 18).

After testing the product with the GEV test method, classification of the product according to the applicable GEV classification criteria and presentation of a valid GEV license, the product can be labeled with the EMICODE®.

Every year, the GEV spends a considerable part of its membership fees (2023: approx. 100,000 Ä) on carrying out spot checks of randomly chosen licensed products. In the event of a violation, the manufacturer concerned must bear the cost of testing and of any further quality checks. In case of doubt, the dispute will be settled by arbitration. Repeated violations may result in the member’s expulsion from the GEV. If any non-compliance with the GEV criteria is detected and reported by a third party, the GEV member concerned will also pay the testing costs of the third party in case of confirmation.

During application, EMICOD® EC 1 and EC 1PLUS labeled products only give off a slight odor and are practically odorless after hardening. Odors from EMICODE® products themselves are therefore not to be expected – provided they are used correctly and expertly. This also includes cleaning and expert preparation of the surfaces to which the product is to be applied. However, it is a well-known fact that the development of odors after finishing or renovation work can have a variety of causes.

These include, above all, so-called secondary emissions. These odor-producing substances can be the result of alkaline moisture, insufficient drying or other causes. It would therefore be wrong to assume that there can no longer be odor complaints in connection with EC 1PLUS products. In the event of a complaint, however, the person who recommended or used an EC 1PLUS labeled product need not be unduly concerned about any ambient air tests that may be performed.

With the exception of purely inorganic, mineral or metallic materials, there are hardly any products that do not emit at least traces of VOCs in one form or another. Organic materials, such as plastics or natural materials, can therefore never be emission-free. Today, with the advances in analytical methods and devices, it is possible to detect an ever-increasing number of VOCs in lower and lower concentrations. This is why emission-free chemical building products do not and will not exist in the future. The GEV therefore considers the use of the term “emission-free” as incorrect and misleading.

In addition to the EMICOD®, there are other national and international labels that provide information on the emissions of building products, e.g. the “Blue Angel” or “Greenguard” in the USA. Series of tests carried out by the GEV have shown that EC 1 labeled products also meet the requirements of these classification systems. Class EC 1PLUS, on the other hand, has set a new benchmark that is currently not matched by any other class in any other system.

The EMICODE® makes a contribution in various areas of “sustainable building”. Further information on this can be found in the various GEV brochures on the subject of sustainability.

Contribution to sustainability — of buildings

Contribution to sustainability — parquet adhesives

Contribution to sustainability — surface treatment of parquet